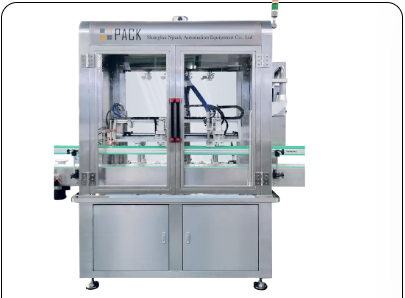

Choosing an appropriate sauce filling machine is essential to both achieve operational efficiency and maintain quality and throughput in your production line. There are a number of machines available now designed to assist with that sauce bottling process in one way or another but, as you might suspect, not every machine you can buy is the same, and the one you choose can, and probably will, either make or break your operation. How do you select the best sauce filling machine for your business requirements.

Assess Your Sauce Viscosity

The viscosity of your sauce really dictates what filling machine you will need. From the thin sauces such as hot sauce vs thick pasty tomatoes paste. Machines made for thin liquids will generally run more quickly but may struggle with thick sauces that need more precise product dispensing (which is achieved by the use of pumps or piston fillers). Be sure the machine you go with is capable of handling the exact viscosity of your sauces, even if that means choosing an option with adjustable filling parameters.

Production Capacity Needs

The number of units you plan to produce determines what size machine you choose. This may be enough if you represent a small or medium size enterprise, but if you are a large manufacturer, 20 to 50 bottles per minute will definitely not satiate your production needs, that are up to a 100 bottles per minute or more as per the industry standards. The machine you select now must be able to scale up with your company, as this is important.

Check Container Compatibility

Whether you are a glass supplier, manufacturer, work with jars or bottles, the kind of containers you have impacts the kind of filling machine you require. While some machines might work better with rigid containers, others are best for flexible packaging. Verify the specs of the machine are sufficient to run your container by height, shape and material as well as change parts required for different sizes or shapes.

Focus on Fill Accuracy and Repeatibility

A sauce filling machine of high quality should be capable of providing accurate filling to guarantee the product weight or volume per container consistently. This helps in keeping the product quality and customer satisfaction afloat with time. Advanced technologies such as servo motors or feedback systems in machines allow for higher accuracy, to eliminate product wastage due to overfills or underfills.

Opt for Convenient Cleanliness and Maintenance

Because of the liquid nature of sauce filling, which can be messy and sticky, it is necessary to select a machine that is easy to clean and maintain. Opt for equipment featuring hygienic design principles including easy-to-remove parts and limited food contact surfaces, which are accessible and cleanable. Stainless steel is also desired over other materials due to its anti-corrosion properties as well as its ease in cleaning.

Consider Automation Features

Below are examples of just how much automated features can improve the efficiency of your filling operations. Some of the latest sauce filling machines may come with a user-friendly touch screen control, programmable settings, automatic adjustments features etc., to make the production process easier and minimise any manual work. Furthermore, these attributes can facilitate more reliable operation and seamless integration with the rest of your line features.

Selecting the ideal sauce filling machine requires a thorough examination of your product traits, production requirements, and operational preferences. If you carefully consider all of these elements, you will be able to choose a machine that can meet and exceed your current needs, support future needs for growth and innovation and is a good long-term choice for your sauce production.